Cnc Beam Drill Line Routing

The CNC Beam Drill Line can be programmed manually at the machine or in the office using the supplied Peddimat software. This software comes included with the AVENGER and can be installed on as many PCs in your office as you choose � this unlimited license is included with the purchase of your machine. It is the same software that is found on the machine itself and is the same software used on the CNC Beam Drill Line and all Voortman CNC fabricating machinery.

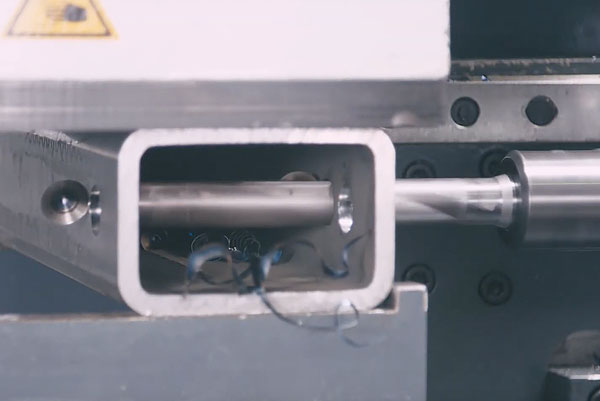

CNC Beam Drill Line: The CNC Beam Drill Line is today's most affordable CNC beam drill system on the market. It allows the fabricator to win more work and make more margin.